No products

Product successfully added to your shopping cart

There are 0 items in your cart. There is 1 item in your cart.

Search

Categories

- Wooden Sword

- Aikido

- Iaido

- Kendo

- Naginata

- Kyudo

- Obi and Belt

- Bag

-

DVD

-

Iaido,Kenjutsu

- Kashima shin ryu

- Shingyoto ryu/Shinkeito ryu

- Kobudo

- Yagyu shinkage ryu

- KURODA Tetsuzan

- Itto ryu

- Battodo

- Grand Masters

- Katori shinto ryu

- Hokushin itto ryu

- Tennen rishin ryu

- Muso jikiden eishin ryu

- Muso shinden ryu

- Kashimajikishinkagé ryu

- Hyoho niten ichi ryu

- Suio ryu

- Yakumaru zigen ryu ( jigen ryu )

- Mugai ryu

- Zen nihon todo renmei

- Yagyu shingan ryu

- Shushin ryu Iai Jutsu

-

Aikido

- UESHIBA Kisshomaru

- UESHIBA Moriteru

- YAMADA Yoshimitsu

- TAMURA Nobuyoshi

- SAITO Morihiro

- Aikikai Hombu

- ISOYAMA Hiroshi

- TADA Hiroshi

- SUGANUMA Morito

- SUNADOMARI Kanshu

- KOBAYASHI Yasuo

- SHIMIZU Kenji

- SATO Tadayuki

- HARI Sunao

- NARITA Shinjuro

- TAKEDA ryu-NAKAMURA ha

- ARIKAWA Sadateru

- SUICHI Kazuaki

- KURABE Shiseido

- HATAMURA Hirokazu

- Other

- Kendo

- Judo

- Daito ryu Aiki jujutsu

- Yoshinkan Aikido

- Ninjutsu

- Karate

- Jodo

- Kyudo

- Sojutsu

- Jujitsu

- Naginata

- Buki jutsu

- Kobudo Taikai

- Yoseikan Aikido

- Hino Budo

- Aunkai

- KONO Yoshinori

- Bujutsu

- Chinese Martial Arts

-

Iaido,Kenjutsu

- Men's

- Women's

- Kids

- Japanese Towel

- Furoshiki

- Japanese Decoration

- Buddhist objects

- Hanko

In 2008, we visited one of the four officially recognized artisan companies for manufacturing wooden swords (Bokuto = Bokken, Jo, Tanto, Shoto ...), "NIDOME BOKUTO Seisakujo"

NIDOME is the family name of the craftsman, Mr. Yoshiaki NIDOME, who welcomed us in his workshop. He has the National Qualification of "Dento kogeishi ( Certification of traditional Crafts)". He was selected by "Dento kogeihin sangyo sinkokyoukai" (an association created by the Japanese government, appointed by the Minister of the Economy in order to preserve and protect the specialists and craftsmen of Japanese tradition).

We mention a large part of our interview, which we have tried to translate as faithfully as possible.

We express our gratitude and deep respect to the NIDOME family who warmly welcomed us. We hope to let our readers know that there are still passionate artisans who continue to perpetuate Japanese tradition and culture.

NIDOME Bokuto Seisakujo

In Japan, 90% of production of Yumi (Japanese archery) for kyudo, bokuto (bokken), shinai (a weapon used in Kendo) and furnitures comes from Kyushu.

In southern Kyushu, there is a small town, called "Miyakonojo".

Miyakonojo is the town of manufacturing bokuto (bokken).

The mountains of southern Kyushu contain forests of oak, loquat, Sunuke (YSU / racemosum). This region is really ideal for growing these trees that are used for bokuto.

Mr. Yoshiaki NIDOME specializes in wooden weapons and is the president of the company. His father, Mr. Kojiro NIDOME settled in Miyakonojo after losing everything during World War II, like all his Japanese fellows. He was looking for a job in where he could exercise his passion for trees and woodworking.

In the 1940s, he founded a company with his wife, a specialized artisan in manufacturing wooden weapons / swords.

At that time there were no automatic machines like today. Therefore, everything had to be done by hand.

After the war, Japan experienced a period of very rapid economical growth. The company experienced a major boom and the sales became considerable.

But with the passing of time, people started training less and less. Therefore, the profit of the company also decreased year after year. In 1960, there were 25 Bokuto manufacturering companies in Miyakonojo, however, only 4 remain today.

The two sons of Mr. Kojiro NIDOME have succeeded their father. In a near future, his grandson (the eldest son of Yoshiaki) will also work with them.

How has the company managed to survive so far?

In addition to the bokuto production our family had crop fields (rice, vegetables ...) which allowed us to earn an extra income. Others were not able to continue their crafts because of a shortage of clients.

Why do we use these trees (oak, loquat, Sunuke and kobutan) for manufacturing bokuto?

Oak is hard, sturdy and resistant to physical constraints. There are actually several varieties of oak in the southern Kyushu region. There are all grades of oaks. The standard oak has tight fibers, and these fibers do not float. The one of southern Kyushu is rather hard, but its fibers float. Red oak is slightly lighter than white one.

Biwa (loquat) is mild but sturdy and it has a beautiful surface. When you are hit with a bokuto in Biwa, you feel nothing at this moment, but after a few days the wound appears. Budokas like to tell this story.

Sunuke (racemosum) is solid and resistant to moisture. The Sunuke is the central part of a tree called Isu (Yusu). It is soft but sturdy and can be of different colour, therefore two products made with sunuke will never have the same colour.

Kokutan (ebony) is very hard, heavy and sturdy. This tree grows slowly.

Before to cut these trees, we must wait:

For oak, we should wait for 70-80 years for manufacturing a bokken, and for Sunuke, Kokutan (ebony) and Biwa (loquat), we should wait at least for 200 years.

When you purchase wood, it is a trunk. We cannot know at the first sight whether the trunk is damaged inside (eaten by insects, for example).

You can only use the parts that are not damaged. For example, if the wood is damaged in the middle of the trunk, you can use only the top section for a Tanto or a Chuto.

How do you make a bokuto?

When you purchase wood, it is a trunk, then you have it cut into slices by a sectional specialist called a Seizaisho.

The wood shuold be dried (dehydrated) outside for one year (see the picture below).

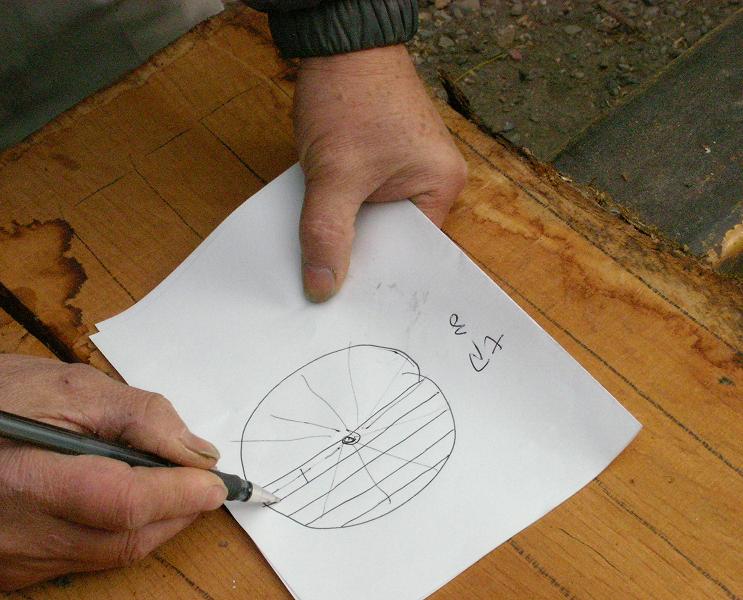

When the wood becomes dry, we draw the design of bokuto on it with a pencil, using the bokuto as a template, then we make the cut.

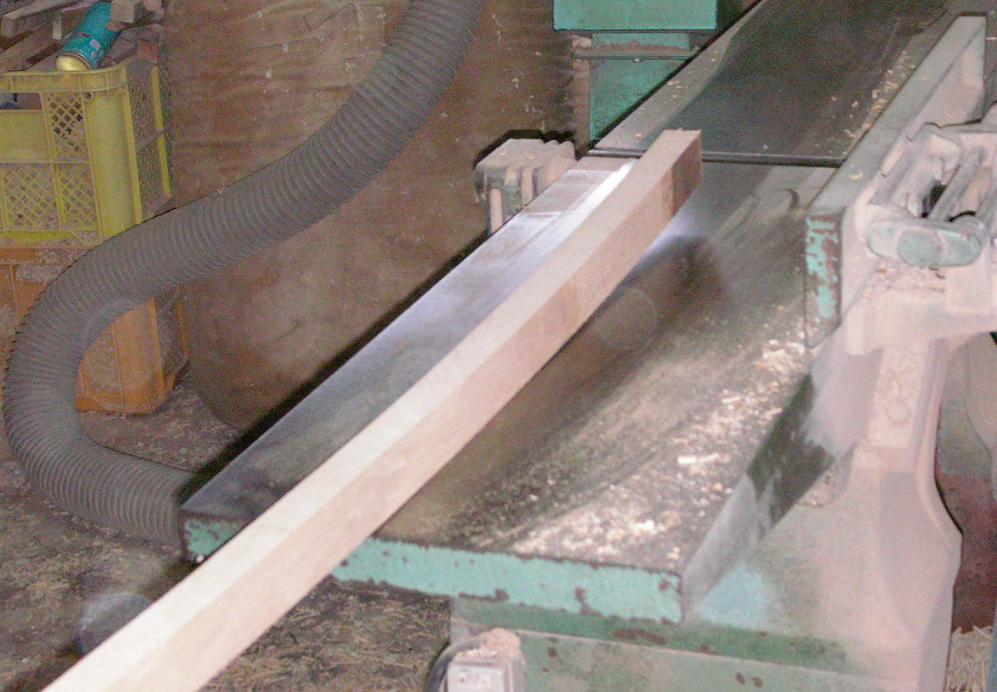

One machine is used to cut through the thickness of the wood, then another machine used for the edge shape. This machine can also be used to shape different bokken.

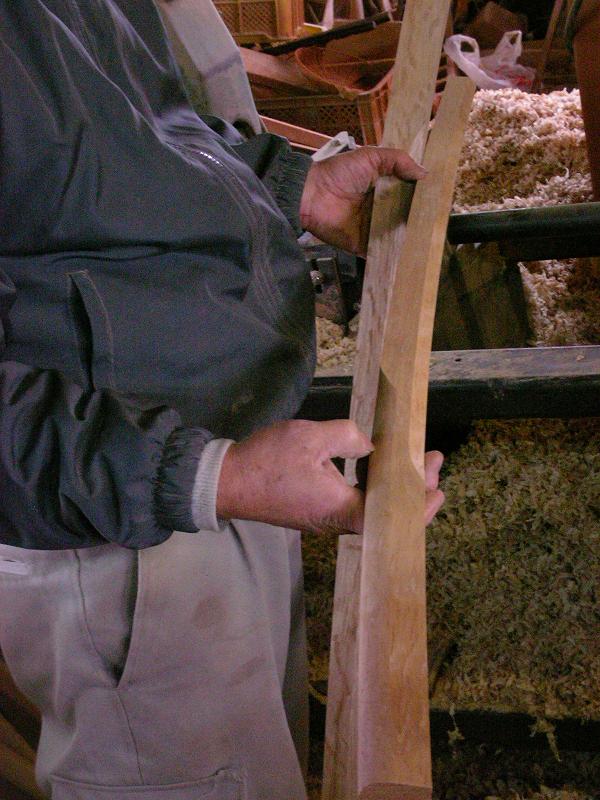

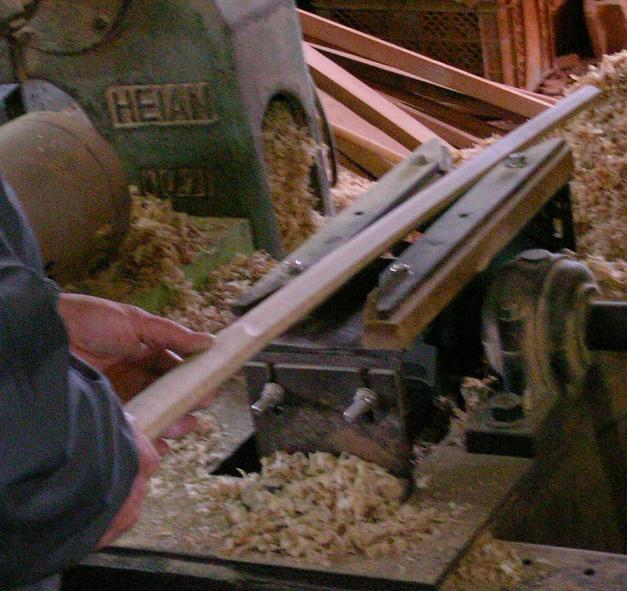

Next, a device is used for shaping the Ha (the "edge" of the bokken); from there, the manufacturing process is made manually. Each bokken has a different blade angle and a different diameter: therefore, you need to use more than 20 planes for all variations.

The bokken is firmely fixed with a special system allowing us to plane it in all directions. This fixing system is unique and was invented 50 years ago in the same workshops in Miyakonojo. Thanks to this system, it is easier to shape the curve blade.

After making various planing operations, the finishing touch are made with a fine sandpaper.

Why do some bokuto twist over the time?

All trees contain the water, the manufactured bokuto also contain the water. To produce a bokken, you need to dry the wood. In other words, you need to eliminate the moisture in the wood. Note that the lower trees are more moistured. In addition, even a tree itself has diferent proportion of hydration inside; the shadow side of a tree which is not exposed to the sun is also more moistured. One side where the sun exposed is less moistured and on the other side, more moistured.

After cutting the wood, leave them to dry over a year, but each tree has a different level of moisture like I said just before.

If a piece of wood is not dry enough, over the time, it will be twisted. If it is dry enough, it will remain straight.

To keep the bokuto dry and clean, bokuto is protected by a piece of plastic paper.

Today some companies use machines to dry wood artificially. (Drying time is only about 15 days!!! Almost 24 times faster than drying naturally!!).

The dry furnace can save the production time and let you keep a few inventory, but the wood will be damaged unlike dried naturally.

If we artificially dried, the wood fibers become shorter and wood "dies" . In removing moisture quickly, the wood will absorb moisture quickly and will be broken more easily. Wood naturally dried in the open air will still "alive" and their life will be very long.

Should we throw bokuto twisted?

No.

We can repair them with the heat.

Look: he gives us a demonstration: the result is spectacular, the bokuto is repared like before

Should we put oil (eg camellia oil) on the bokken to protect it?

No, it does not work at all in Japanese climate with such humidity. Some Budoka (practitioners of Japanese martial arts) like to put oil on their bokken, but only for the beauty !!. After a few years the oil will be absorbed by the bokuto. Nothing works but natural fat covered on the surface of your hands can "greases" your bokuto and your jo !!

How do we keep a bokuto? Should we put it in the vertical or in the horizontal ?

It is better to put it horizontally. If you put your bokken vertically, the temperature of the atmosphere varies from the top to the bottomf of the bokken. However, if you put it vertically, the temperature is the same in any part of the bokken.

There Are only 4 suppliers in Miyakonojo. Does each manufacturer produce different bokken and Jo ?

Yes, each company has its own expertise.

The sori (an arc of a sword) is different. In our company, the sori is not so curved called Koshi-zori, but another manufacturer has the "middle/ midway" sori called Naka-zori. Another has the top called Saki-zori. It should be difficult for clients to see the differences in the four types of arc, but I can distinguish 4 types of bokuto manufacturers.

Do your bokuto have a particular characteristic?

The manufacturers produce bokken according to customer portfolio. We also manufacture "tailored" bokuto. It depends on special requests by our clients. Normally the suppliers do not like to make "special" bokuto because it spends more time to make it than serial ones.

Other suppliers send some clients who want a custom order to us (NIDOME). we try to meet maxmum needs of clints. The deadline is a little bit longer than that of standard one. But at least you can have your original bokuto as you wish.

When there were over 20 companies, we competed each other, but now we are only 4. We get along with each other.

Which process is the most difficult to manufacture?

For over 30 years I've been doing this, so, today it is not too difficult for me, but I always pay attention to things to which people do not pay attention. For exemple, the sori (the arc, the shape of a blade) is a part of bokuto that people do not look carefully either ...... I like that the finishing of my bokken is perfect.

Are you threatening the Chinese-made products?

For the moment no. Right now the Chinese bokuto has an average quality. The bokuto in the souvenir shop, there is no value.

In the case of Kendo, almost all Bogu and Shinai are manufactured in China today. They are cheaper than these of Japan-made. Manufacturing techniques have progressed in China. Because the Japan does not developed its techniques. Today, you can not train young people because they are not interested in doing thih kind of job. There are only the old.

I fear that a visitor comes as you ask me to show my studio and then he will make bokuto in China one day, because it already happened like as I said for kendo equipment.

I do not like to force my son to succeed my job. In my case, I had no choice. I had to work with my father and his successor. I always tell my son; it's up to you! you can choose your profession. He wants to work with me to take over. He is still young.

He are working another atlier to learn all skills that he needs to be professional craftsman.

|

|

hen the wood becomes dry, you draw the desing of bokudo on it with a pencil and cut.

|

||

|

We cut the wood as avoiding damaged parts. |

Template |

||

|

to decide its thickness,

|

then one machine is used for the shape of the edge of bokken.

|

||

|

|

|

||

|

|

|

||

|

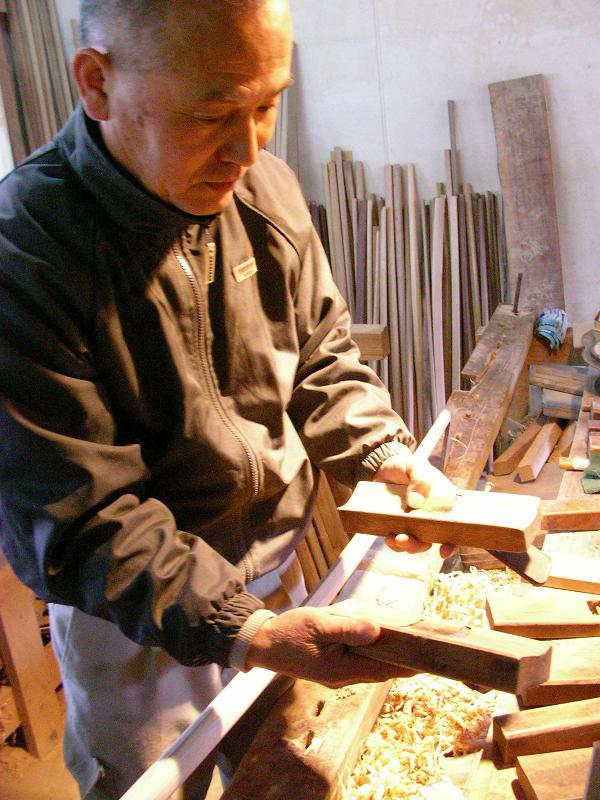

He is planing the part of Tsuka

|

He is shaping a part of bokken to place a Tsuka |

||

|

|

Planing Each bokken has a different blade angle and a different diameter: therefore, you need to use more than 20 planes for all variations. |

||

|

|

|

||

|

|

|

||

|

Planing in the shape that you can put a Tsuka.

|

|

||

|

The cherry brand is the official brand of the Ministry of Defence. |

This bokuto is orderd by the Ministry of Defence |

||

|

Mr.NIDOME (2 brothers) |

His mother (right) to create Nidomé bokuto Seisakujo with her husband. |

||

|

Wood Specialties in Miyakonojo

|

|||

|

Miyakonojo Yumi |

Miyakonojo bokuto |

Shinai |

Furniture |

| We went by train "Shinkansen Hikari" and express "Kirishima" "Kyushu shinkansen-Tsubame"

"New Kyushu shinkansen-Tsubame".

|

|||